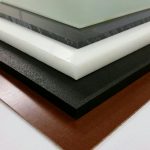

Foam PVC materials are light weight and durable with a surface characteristic suitable for painting, engraving, milling and screen printing. Unmodified polyvinylchloride is a rigid thermoplastic. Its flexibility can be increased by adding dioctyl phthalate and other plasticizers.

One of the common methods of PVC processing is through suspension of solid particles of the polymer. Plastisol is heated resulting in homogeneous system which cools and becomes a flexible solid. Since its first introduction in 1930 it is widely used in myriad of films and molding to extruded pipe.

PVC foam has an excellent resistance to water and aqueous solution. Several copolymers and alloys are possible with PVC including acrylonitrile and styrene. Rigid PVC is still, strong, low cost plastic material that can be easily fabricated and can be joint with adhesives or solvents. The material can be easily weld using thermoplastic and is frequently used during the construction of tanks, piping systems, and valves.

PVC Properties

- Low cost

- Stiff and strong

- Easy to fabricate and machine

- Easy to weld using thermoplastic welding equipment.

- Easy to join adhesives and solvent.

- Low flammability

- Uniform cell structure

- Good resistance to light and weathering

- Sound and thermal insulation to absorb oscillations and vibrations.

- Mate surface ready for vinyl’s, paint and ink.

PVC Applications

- Valves and pump house

- Manifolds

- Fittings

- Piping systems

- Working surface and cabinets

- Welded chemical tanks

- Used in kiosks

- Used in fixtures and shelves

Industries using PVC

- Display companies

- Sign companies

- Exhibit companies

- Store fixture companies

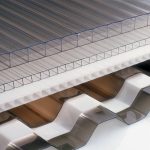

Standard Sizes

Sheet

Thickness:

0.062 in – 4 in

Dimensions:

12 in x 12 in – 60 in x 120 in

Rod

Outside Diameter:

0.250 in – 14 in

Grades

- CPVC

- Type 1

- Type 2

Additional PVC properties

- CPVC – Corrosion and high heat resistance PVC sheet that can resist corrosion at an elevated temperature.

- Type 1 – Excellent corrosion, and chemical resistance, which are easy to fabricate, machine or weld with normal impact.

- Type 2- Excellent corrosion resistant at an elevated temperature with high impact.

- Bonding PVC – Easily achieved through fast setting of methacrylate adhesive to create a stronger bond.

General PVC Properties

|

Properties |

Units |

ASTM test |

PVC |

||

|

Tensile strength |

Psi |

D638 |

7500 |

||

|

Water absorption |

% |

D570 |

0.06 |

||

|

Izod impact |

ft-lbs/in of notch |

D256 |

1.0 |

||

|

Flexural modulus |

Psi |

D790 |

481,000 |

||

|

Maximum temperature |

°F |

– |

140 |

||

|

Heat deflection temperature |

°F |

D648 |

158 |

||

|

Coefficient of linear thermal expansion |

in/in/°Fx10-5 |

|

3.2 |

Note: Values may differ according to the brand.