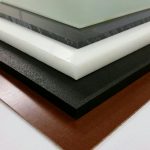

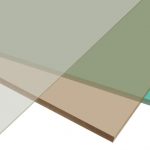

An Acrylic is a transparent thermoplastic homopolymer material which is similar to polycarbonate. It is suitable for the use of impact-resistant alternative to glasses with high impact strength. Known as the most common material, plastic sheets are available in several colors. The raw materials allow internal transmission of light; therefore, it works as a wonderful substitute.

The acrylic material is very much similar to polycarbonate. The only possible difference is that it contains no potentially harmful substances such as bisphenol-A (BPA).

These are readily available inexpensive materials and a good alternative to Polycarbonate with good scratch resistance features. If you are looking for Acrylic in Sydney, give us a call.

Product Features

- Impact-resistant

- Good optical properties

- UV stabilized

- Easy to cut

- Thermoformable

- Excellent sound abatement properties

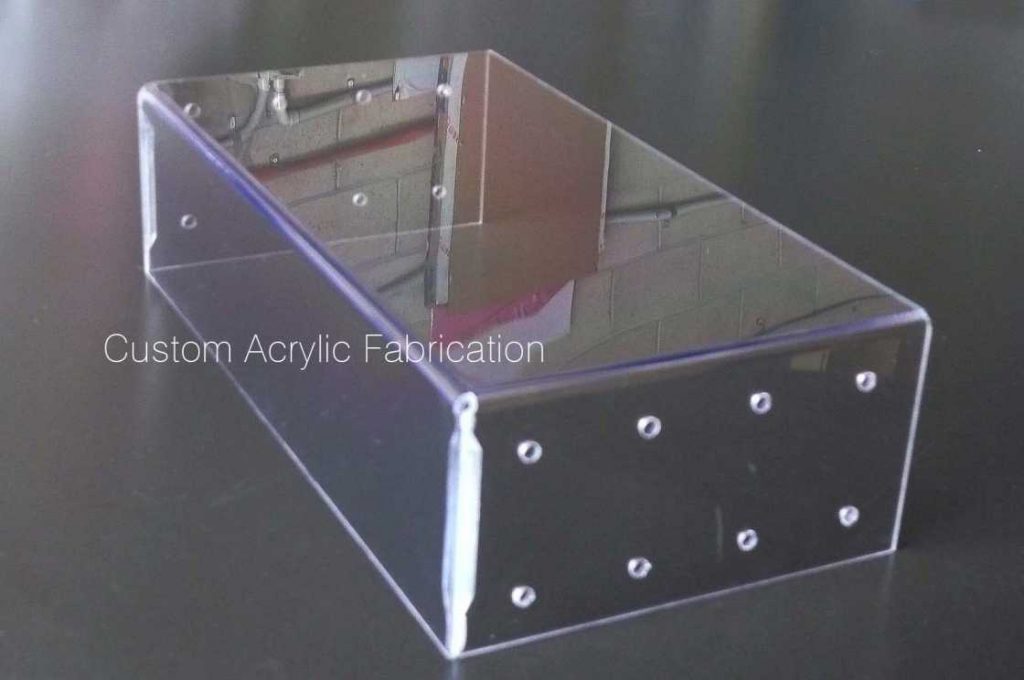

- Versatile, and suitable for fabrication

Product Applications

- Aquarium

- Point of Sale

- Models

- Windows & Doors

- Medical

- Graphic lights

- Lighting

- Signage

- Furniture

- Exhibits

- Boat and Motorcycle windscreen

Standard Sizes

Rods

Outside the diameter

(0.250in – 6 in)

Extruded outside diameter

0.062in – 3 in

Extruded square outside diameter

0.125 in – 15.00 in

Sheets

Dimensions

22.5 x 46.5 in – 72 in x 120 in

Thickness

0.010 in – 2 in

Tubes

Cast outside diameter

1.250 in – 12 in

Extruded outside diameter

0.250 in – 6 in

GRADES

- General purpose

- Abrasion resistant

- 40% impact modified

- 70% impact modified

- Bullet resistance

- Digital

- Anti-reflective/Non-glare

- Sign grade

- ESD (Electrostatic Dissipative)

- Light diffusing

Note: Length, width, diameter, thickness can vary by brand, manufacture and grade.

GENERAL ACRYLIC PROPERTIES

|

Properties |

Units |

ASTM test |

Processed acrylic sheet |

||

|

Tensile strength |

psi |

D638 |

10,000 |

||

| Water absorption |

F |

– |

160 |

||

|

Izod impact |

|

D256 |

0.4 |

||

|

Flexural modules |

psi |

D790 |

480,000 |

||

|

Heat deflation temperature |

F |

D648 |

195 |

||

|

Coefficient of linear thermal expansion |

in/in/°Fx10-5 |

D696 |

4.0 |

ADDITIONAL ACRYLIC PROPERTIES

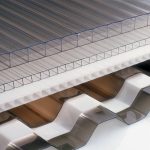

Extruded Acrylic – The acrylic sheet can be manufactured in any length. Which minimizes material and financial loss. The sheet can be fabricated in a customized size. Extruded acrylic is the easiest grade of thermoforming and the easiest bond using solvent cement.

Cast Acrylic – These sheets have better chemical resistance with superior characteristics higher than extruded acrylic.

Acrylic for architectural applications – It is light weight and weather resistance which makes this a popular choice for architects. From lightning fixtures to canopies acrylic sheets can be used in every space.

FDA Complaint Acrylic – It is available in FDA complaint grades.

Cut to size Acrylic sheets – It is available in ‘cut to size’. Gain the flexibility of buying acrylic sheets. Save time, eliminate scrap, reduce wear and improve productivity.

Acrylic packs – Different grades of acrylic sheets are sold in much more convenient pack ranging from 4-12 sheets.

Note: Value may vary according to the brand name.

Know more about the Acrylic Sheets and color availability. Contact us!